Forget offshoring—the future of manufacturing is off-world.

United Semiconductors is collaborating with Aegis Aerospace on a new in-space manufacturing facility to produce essential semiconductor materials, the companies announced yesterday.

Division of labor: The partnership will combine United Semiconductors manufacturing expertise with Aegis Aerospace’s newest in-space manufacturing platform, both of which were honed with the help of government grants.

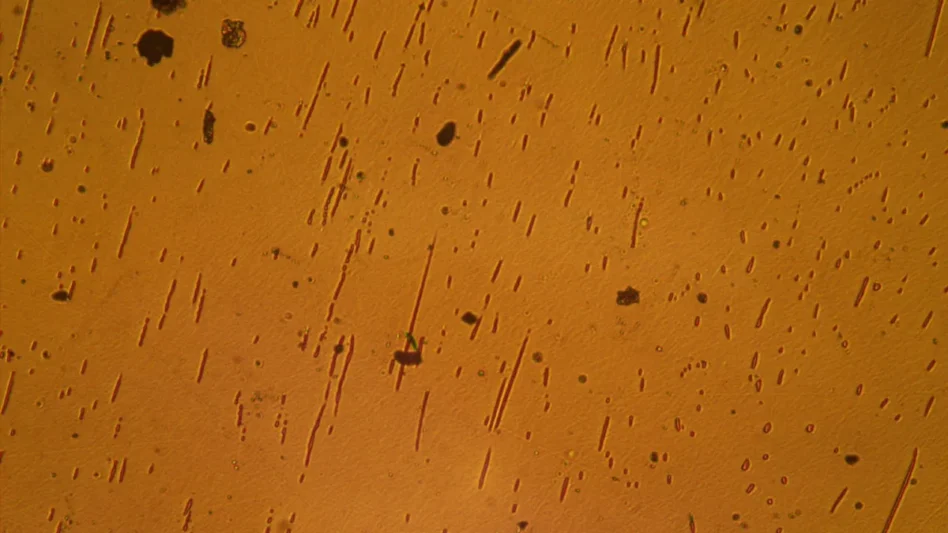

- In 2022, United Semiconductors won part of a $21M prize to perform experiments onboard the ISS, as a part of NASA’s “In Space Production Applications” initiative. The company has since sent manufacturing experiments on two missions to the ISS, in 2024 and 2025, respectively.

- Going forward, United Semiconductors aims to send that manufacturing process to space aboard Aegis’ Advanced Materials Manufacturing Platform (AMMP), which is being developed following a Texas Space Commission grant worth up to $10M.

Together, the goal is to commercialize the in-space semiconductor manufacturing process to tap into the growing demand for high-quality semiconductors, which in turn is fueled by the rise of AI and quantum computing.

Matt Ondler, president and CSO at Aegis Aerospace, told Payload he expects the AMMP demonstration on the ISS as early as late 2027.

“The ultimate production unit will be able to be hosted on future space stations or unmanned free fliers and can be scaled as on-orbit infrastructure grows,” Ondler said.

Diversified portfolio: While Aegis and United Semiconductors say their partnership will create the first “dedicated commercial facility for in-space material production,” Aegis is not the only space company pursuing in-space manufacturing with the help of United Semiconductors.

- In September, United Semiconductors partnered with Wales-based startup Space Forge to develop a plan for commercial semiconductor production on orbit. This partnership may rely on Space Forge’s Pridwen heat shield to bring semiconductor materials home safely.

- In October, the semiconductor firm announced a multi-flight joint development agreement with Varda Space Industries, to produce semiconductors on-orbit.