Semiconductor manufacturing is big business, and a new startup from Washington, DC has plans to take it out of this world.

Besxar Space Industries emerged from stealth yesterday with the announcement of a launch deal with SpaceX. The launch giant will fly a total of 24 of Besxar’s reusable in-space manufacturing payloads aboard 12 upcoming Falcon 9 launches—with the first launch expected as soon as this year.

As part of these missions, Besxar’s “Fabships” will integrate into the first-stage booster of a Falcon 9 to launch to space, run a manufacturing process, and return home safely.

Meet Besxar: Besxar was founded in 2023 by Ashley Pilipiszyn, who saw the growing mismatch between the semiconductor manufacturing process and the needs of new technologies, as an early employee at OpenAI.

“We’re in a world where there is 24/7 throttling, and today’s chips—truly—the GPUs are melting,” Pilipiszyn told Payload. “It really boils down to having next-gen materials that could withstand this 24/7 throttling because, ultimately, data centers have become the new extreme environment.”

Making semiconductors on Earth is full of downsides, according to Pilipiszyn. Manufacturers are investing heavily in vacuum technology to remove as many contaminants as possible and develop the best semiconductors. These silicon semiconductors, however, still aren’t strong enough for the demands of new technologies: AI data centers, directed-energy weapons, etc.

By taking the manufacturing process to orbit, Besxar is able to use the ultra-high vacuum of space to manufacture better semiconductor wafers for a fraction of the cost—even when factoring in the costs to get to space and back, according to Pilipiszyn.

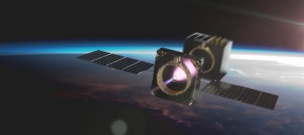

The printing press: Besxar will spend its SpaceX flights fine tuning the technology inside Fabship, a spacecraft about the size of a microwave, before scaling up.

Fabship is the first reusable payload to fly on a SpaceX rocket, according to Besxar. This means Besxar can aim to quickly iterate on the technology to not only ensure its manufacturing process is well protected from the shock of launch and reentry, but also to ensure that the company is churning out the best possible materials.

Fabships are designed to be launch-vehicle agnostic. Down the line, Besxar plans to ramp up its process to meet the growing demand for high-quality semiconductors—increasing its production capacity either by flying larger Fabships, spending a longer time in orbit, or flying more regularly.