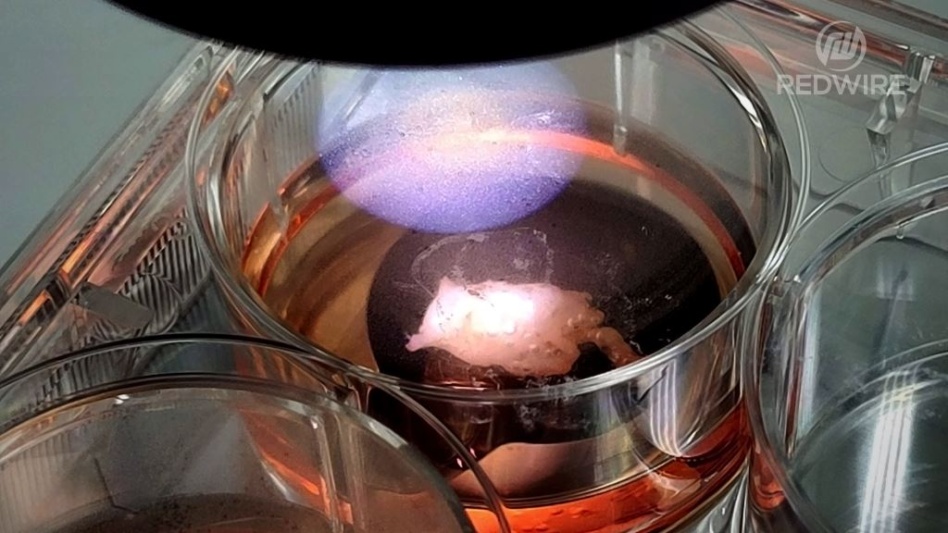

When the SpaceX Dragon returned to Earth from the ISS on April 30, it returned 4,100 lbs. of cargo, but its most exciting payload may have been a tiny blot of cells—the first living cardiac tissue to be bioprinted in space.

The tissue was produced by a Redwire Space ($RDW) biofabrication module installed last year on the orbital lab.

Heart disease is the world’s leading cause of death, and researchers are eager to develop artificial tissue that can be used to repair injured hearts, and eventually create transplantable organs. Growing the organs in microgravity can make it easier to replicate the 3D structure of natural tissue.

The long game: The project is part of Redwire’s efforts to demonstrate that it can reliably produce biological products that benefit from microgravity—a first step toward a long-term goal of regular production. The company has already printed an artificial meniscus using this facility, and its next goal is to bioprint human blood vessels in space.

Redwire also returned 36 experiments from another of its modules, this one designed to grow pharmaceutical crystals in space. It is currently using that facility to perform research for pharma giant Eli Lilly.

“These are extraordinary scientific achievements that bring us closer to reliable, large-scale commercial biotech services on orbit,” Redwire In-Space Industries President John Vellinger said.

Investor notes: Redwire reported $87.8M in revenue for the first quarter of 2024 yesterday, a more than 50% increase year-over-year.

Also on that Dragon: Samples of 7+ miles of ultra-efficient ZBLAN fiber optic cable produced in a fabricator designed by Flawless Photonics. This year, the company blasted through the previous daily product record of 82 feet when it manufactured half a mile of fiber in one day.

Flawless can sell the fibers for $1,000 a meter, and is working to increase production and quality control with partners including Axiom Space.