3D metal printing is getting a makeover. Rosotics, a Mesa, AZ-based startup designing a more efficient, large-scale 3D printer optimized for the needs of the aerospace industry, announced this morning the closing of a $750,000 pre-seed round.

The round was led by Draper Associates with participation from Correlation Ventures, Vibe Capital, and Sequoia Capital. That’s the second space-focused announcement in the last two weeks we’ve seen from Draper, a storied Silicon Valley VC firm, but who’s counting…

3D printing’s pain points: Machines on the market today are inefficient, dangerous to operate, and can’t produce big enough structures for many applications, Christian LaRosa, Rosotics’ founder and CEO, told Payload.

“Traditionally, the way a very large metal structure is created…is you apply heat externally by using a laser, and that heat is used to liquefy a wire into a metal fluid, which then solidifies,” LaRosa said. “The problem is lasers are a very inefficient way to deliver heat and to deliver energy.”

Size is also an issue. The aerospace, marine, and energy industries all require very large components that can’t be built in one piece using additive manufacturing as it exists today.

Rosotics’ solution

To solve the problems associated with traditional 3D printing techniques, LaRosa and his team have invented a new way to print metals called “rapid induction printing.”

Essentially, the technique takes advantage of the conductive property of metal to generate heat from within the feedstock. “What that does, at the end of the day, is you’re able to create hardware that is a lot more efficient and simple and less dangerous for the people who operate it,” LaRosa said.

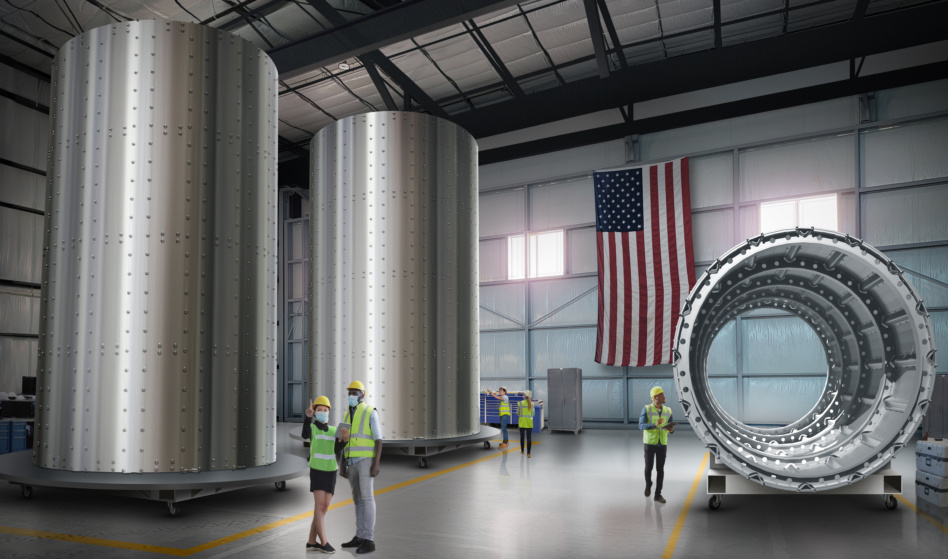

The Rosotics team of 10 has been working out of a pair of airplane hangars at the Mesa airport. There, they’ve designed and built a prototype printer. Mantis, as the prototype is called, is designed to fold up into a small, transportable package, then unfold when needed to 3D print structures between 1.5 and 8 m across and 9 m high in aerospace-grade steel and aluminum.

What’s next? With the closing of its pre-seed, Rosotics is focused on bringing its product to the aerospace market. That includes delivering the first Mantis prototype to an unnamed customer in Q1 2023 and starting to build out a future sales pipeline.