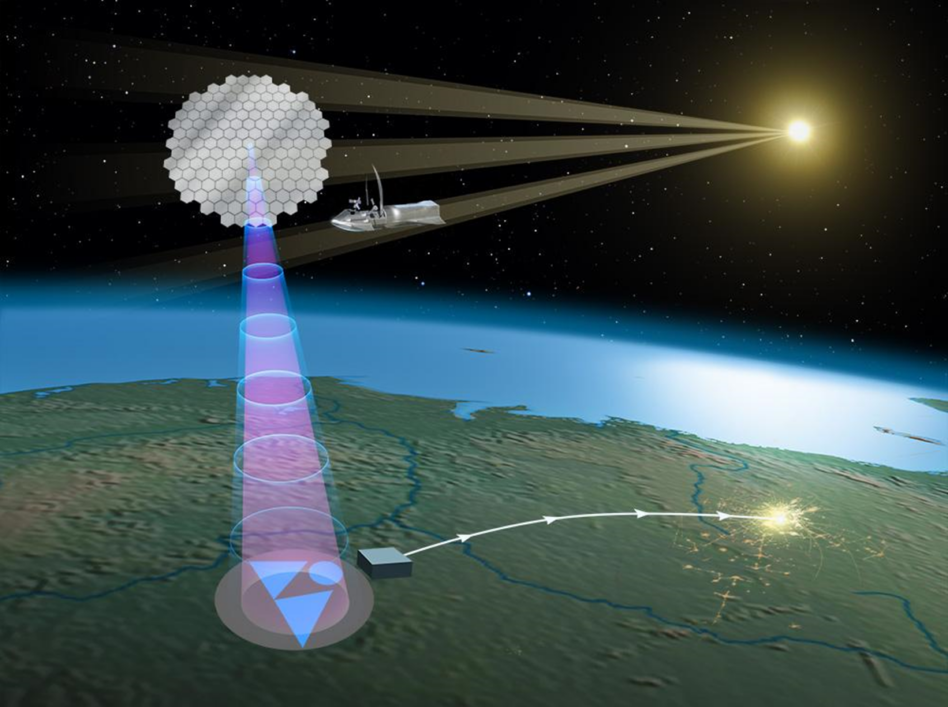

Two startups are working together to build the world’s first commercial space-based solar power (SBSP) station which will capture the Sun’s energy in orbit and wirelessly transmit it to Earth for continuous use.

Orbital Composites and Virtus Solis announced the MOU yesterday for the station, which will use photovoltaic arrays to collect solar energy in space.

The players:

- Orbital Composites is an advanced manufacturing company that uses 3D printing to mass produce SBSP satellites with phase-arrays and power electronics. It already has partnerships with other major players in the space industry such as the US Space Force, Axiom Space, Northrop Grumman, and Lockheed Martin.

- Virtus Solis is an early-stage deep tech startup incorporated in 2019 that focuses on wireless power transmission (WPT) technology. The company uses microwave WPT to make the transfer of solar energy from space to ground more efficient, and aims to keep energy costs low enough to replace fossil fuels globally.

Better together: Virtus and Orbital connected at Seraphim’s Generation Space Accelerator Mission 11 in April and solidified a partnership over the following months. Virtus plans to progress from a proof of concept phase to a manufacturing process development phase over the next 18 months.

“Orbital Composite’s manufacturing as a service capability will accelerate the development of Virtus Solis’s tile satellite architecture and progress it towards mass manufacture with a first on-orbit test in 36 months of 100+ satellites,” said John Bucknell, CEO and founder of Virtus.

Dividing responsibility: The core SBSP technologies — antenna arrays, power electronics, and modular mega-structures — will be designed by Virtus, while Orbital will leverage its expertise in robotic manufacturing to develop scalable manufacturing processes and produce 3D printed phase-array antennas and turnkey satellites, as well as the in-space service, assembly, and manufacturing (ISAM) of the Virtus SBSP station.

“Virtus’ Space-Based Solar Power stations exemplify Orbital’s vision to do high-volume manufacturing and assembly of some of the largest structures ever made in-space,” Orbital CEO Amolak Badesha told Payload. “Short-term, we get an amazing customer that pushes our technology forward to deep integration between electronics and composites. Long-term, Virtus represents one of the largest commercial opportunities for ISAM, with the potential to transform the worldwide energy landscape.”