ispace US unveiled a new headquarters on Thursday that will serve as the homebase for its mission to establish long-term lunar infrastructure and the birthplace of the company’s newest lander.

The lunar tech company, a wholly-owned subsidiary of the Japanese entity of the same name, has ambitious goals to land craft on the Moon consistently to help establish a long-term human presence there. Its new facility in Denver and its new lander, dubbed APEX 1.0, are the next steps in helping it to get there.

ispace US is working on completing a Commercial Lunar Payload Services (CLPS) mission for NASA in partnership with Draper, and plans to leverage its new lander design to get it done. Subbing in the new lander, however, has delayed the mission a year to 2026.

Building the lunar economy: ispace’s mission hinges on a grand vision for the future of the space economy. To get there, it’s starting with building lunar landers. ispace’s Mission 1 lander crashed on the Moon in April, and the US subsidiary has been doing its part to learn from those mistakes and incorporate them into its future designs.

- ispace, the parent company, has invested $40M+ in its US operation, the company said in a statement.

“We need to be putting these things out on a regular basis,“ ispace US CEO Ron Garan told Payload. “Like the Model T coming down the assembly line.”

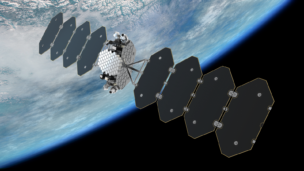

APEX 1.0: ispace US is currently in the design phase for its new lander, which incorporates a slate of new capabilities:

- Launch flexibility

- Dedicated satellite bays

- Additional deployment capabilities

- Improved structure and vibrational resistance

- 500 kg target payload capacity

The first APEX 1.0 mission will fly a straight shot to the lunar surface and allow the lander to ferry 300 kg on the trip.

Digs in Denver: Since Garan joined the company as CEO in July, the company has grown from ~50 employees to “pushing 90,” Garan said. It expects to have more than 100 employees on board by the end of the year.

The new facility in Denver can accommodate that team and more, as the company eyes further growth in the future. Though they aren’t yet up and running, Garan said there are plans in the works to bring manufacturing and testing at a large scale in-house, too.