Burlington, VT-based Benchmark Space Systems has formally expanded across the pond. The propulsion provider has pond-hopped across the Atlantic, not Lake Champlain, just to be clear.

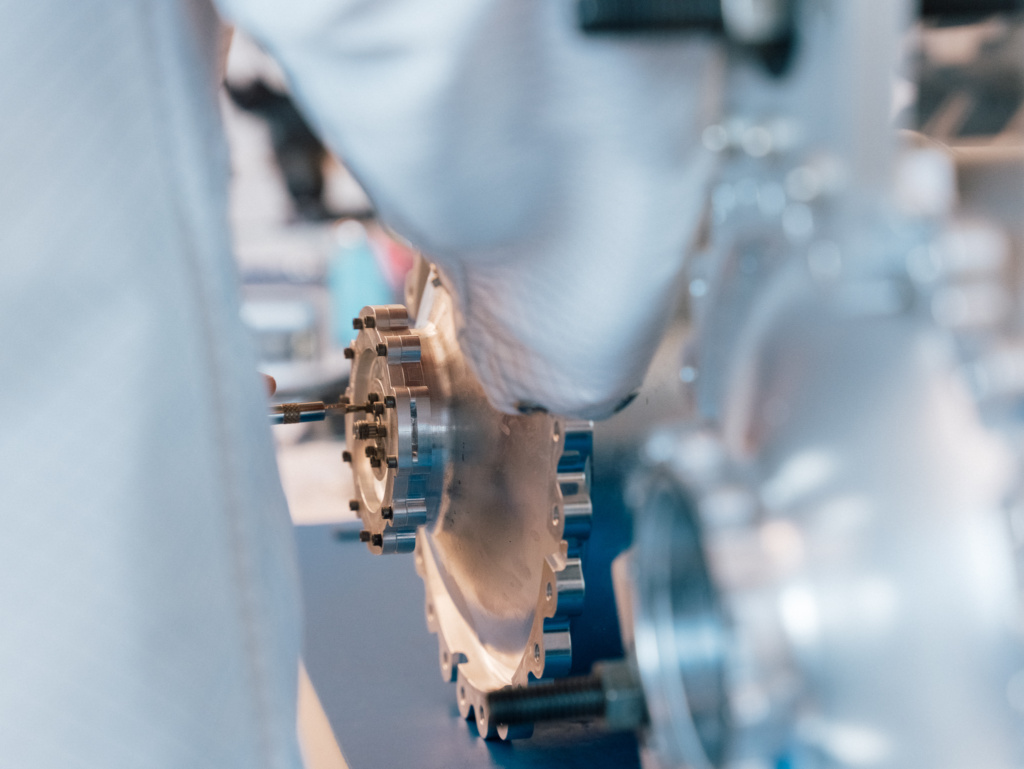

Driving the news…Benchmark has opened a new UK facility to serve the British and European markets. The Vermont startup has also signed a deal with Space Forge, a British in-space manufacturing startup.

Land and expand

Mark Arthur, Benchmark’s European lead, told Payload that the UK operation will be making products by year’s end.

- Benchmark set up shop in Westcott Venture Park, which for decades housed production for British guided missiles and R&D vehicles. The area is still dense with propulsion talent, per Arthur.

- Benchmark secured production and testing space from Satellite Applications Catapult, an organization focused on growing the UK commercial space market.

- “You always want to be close to your customers,” Arthur said. Alas, Westcott is a two-hour drive from Space Forge’s HQ in Cardiff, Wales.

- Benchmark will ship units to Space Forge and unannounced European customers.

The right customer profile

Benchmark has eyed a European expansion for two to three years. The continent has a strong interest in high-test peroxide (HTP) propellants. Arthur said his company has loads of flight experience and familiarity with the greener power source. ~25% of the general propulsion requirements in North American specify non-toxic or green propellant, but the percentage is much higher in Europe.

What’s more, Benchmark can build European systems without having to worry about the stringent US export control measures imposed on ITAR-controlled products.

Space Forge’s POV

CEO Joshua Western told Payload that Space Forge selected Benchmark for its heritage, performance, and willingness to iterate.

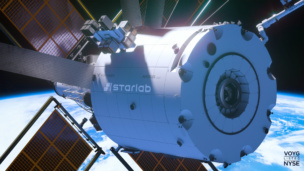

The two companies will co-develop a reusable version of Benchmark’s chemical propulsion systems. If successful, Space Forge can show the industry “satellite technology beyond single use.” But since “nobody’s done it before,” unit economics and other questions still need to be worked out, Western said.

“The cost of return from space has only increased” on a per-kilogram basis since the Space Shuttle’s retirement, Western said. And there’s a “bottleneck” facing those who want to bring back experiments from the ISS.

Space Forge aims to validate its manufacturing payload and reentry capsule on the ForgeStar Orbital Vehicle 1, set to launch next year.

A new market?

Western predicts an “explosion in the downmass market” this decade. Reentry services will start with LEO, he said. They’ll eventually scale to in-situ resource utilization (like asteroid mining) and the lunar surface.

“Space Forge will quite likely be the first reentry in the UK space market,” Arthur said. The US also has multiple players with their sights set on microgravity manufacturing and/or reentry.

- Redwire ($RDW) recently hosted NASA Administrator Bill Nelson to show off existing and future in-space manufacturing missions.

- Varda, a well-capitalized startup, has booked Falcon 9 rideshares for its first microgravity factories.

- Manufacturing also represents a potentially juicy revenue stream for commercial space station developers.

Payload’s takeaway: At-scale, in-space manufacturing has been a fantasy for a long time. The weightlessness, ultra-high vacuum, extreme temps, and microgravity of space make this vision attractive…in theory. But before companies make fiber optic cables or pharmaceutical goods in space and ship them back to Earth en masse, they’ll need to validate early testbeds in demo missions.