The good-luck pancakes were flying off the griddle when Planet’s third and fourth Pelican satellites deployed from a SpaceX Falcon 9 on Tuesday.

Well over 100 Planeteers were gathered in the company’s San Francisco HQ to watch as the satellites—the first to roll off the company’s ramped production line, a few stories below the pancake-eaters—arrived in orbit.

“Pelicans in space,” CEO Will Marshall called out to cheers. “Now, it is in our hands.”

Specifically, the hands of James Mason, Planet’s chief space officer, responsible for the company’s spacecraft development, manufacturing, and operation. Payload caught up with Mason in Planet’s “Mothership,” while his newest spacecraft began coming online.

Hitting cadence: “The first two Pelicans were built essentially by our engineering teams, but these two were built by our manufacturing teams,” Mason told Payload. Planet’s production line reached full speed last month, and “[now] we can get really efficient about how we scale, and we can set up parallel production lines, and hire more technicians, and build them faster.”

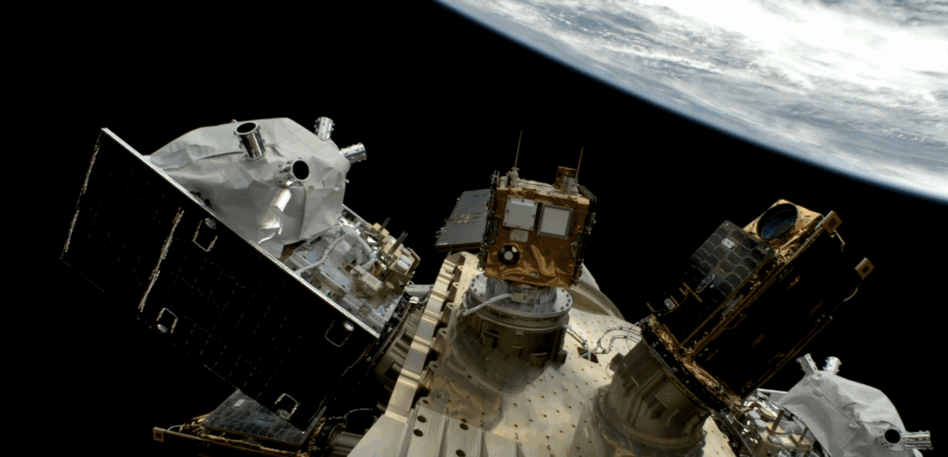

Pelican push: The Pelican spacecraft are designed to replace Planet’s retiring SkySats. Pelicans are the high-resolution complement to Planet’s fleet of SuperDove spacecraft, which image the world’s landmass daily at lower resolution.

The company plans to fly 30 Pelicans, which will allow revisits to any location on the planet every 30 minutes. That constellation will include ten Pelicans, whose capacity will be prioritized for Japan’s SKY Perfect JSAT under the terms of a $230M deal.

Mason wouldn’t say when the constellation will be complete, but noted the company will launch “a few more” Pelicans before the JSAT-focused satellites start heading to orbit. Next year, the company expects to begin launching a “Gen2” Pelican capable of higher resolution imagery.

LOADING: “The last launch [commissioning] was still quite manual, but this one’s all automated,” Mason told Payload. “We’ll basically command the satellite, start your commissioning sequence, and then we’ll just have people basically watching the progress and making sure nothing goes wrong.”

Automating checkouts and software updates lets Planet’s operations team focus on troubleshooting efforts. “From day one, we knew we couldn’t scale manual operation, so we had to build the software to operate the satellites,” Mason said.

Hallucination check: Planet has been using AI techniques to generate insights from its data, but what about on orbit?

“We’re starting to use it more and more on internal productivity, but that includes software development—including for the satellite software and mission control software,” Mason said. “It makes people like me much more productive, who are not very good programmers. But I think for our hardcore firmware software developers, the jury’s still out.”

Mason says the next class of Planet interns may well be tasked to apply generative AI tools to some of Planet’s problems to see what solutions they come up with.

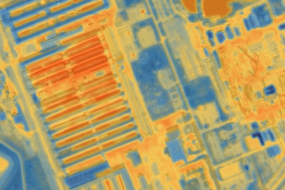

Stay hyperspectral: Mason said the company’s second Tanager satellite, equipped with a high-end hyperspectral imager, is in production. Data being collected from the first Tanager, launched last year, is now being certified for use under some existing Planet contracts—as well as its tentpole mission serving the California Air Resources Board.