Ursa Major will buy several industrial 3D printers and hire 15 new employees for an R&D center in Youngstown, OH focused on additive manufacturing.

The CO-based US rocket engine maker will contribute $10.5M in capital investment, alongside a $4M grant from JobsOhio, a privately-funded economic development non-profit.

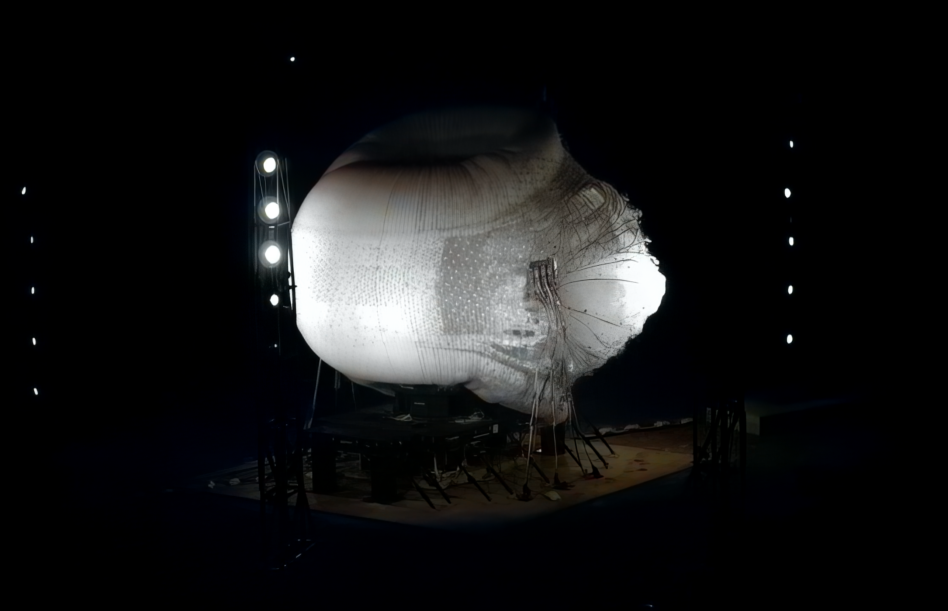

The expansion of a small existing facility will enable the company to step up its development of solid rocket motors—a top priority for the DoD.

Get your motor running: In April, Ursa won a contract of undisclosed value from the Navy to develop a lower-cost manufacturing approach for the standardized solid rocket motors used across a range of missiles. The US supply chains for those motors—mainly provided by Northrop Grumman and L3Harris—have been stressed by US support for Ukraine’s defense against Russian invaders.

“Right now, a lot of it is solid rockets, a lot of iteration,” Ursa Major COO Nick Doucette said of the Youngstown facility, which develops metallic alloys used in motor production. “We are testing our rocket motors multiple times per day.”

Growth opportunity: In November, Ursa raised $138M to support its push into solid rocket motor manufacturing, in a round that reportedly valued the company at $750M.

Last year, when the company unveiled its Lynx solid rocket motor, it said just one additive machine could produce over 1,650 motor casings for the Javelin anti-aircraft missile in a year, compared to the current annual rate of 2,100 for the entire industrial base.

Made in America: The Ohio R&D center also produces components for products across Ursa’s product line, including the liquid-fueled Hadley engine that flew for the first time this year.

“You constantly hear about [strengthening] the defense industrial base,” Doucette said. “If you really break down what that is, we need to make sure we have core skilled talent that manufactures real hardware in this country, period. We’re super proud to be part of that push.”