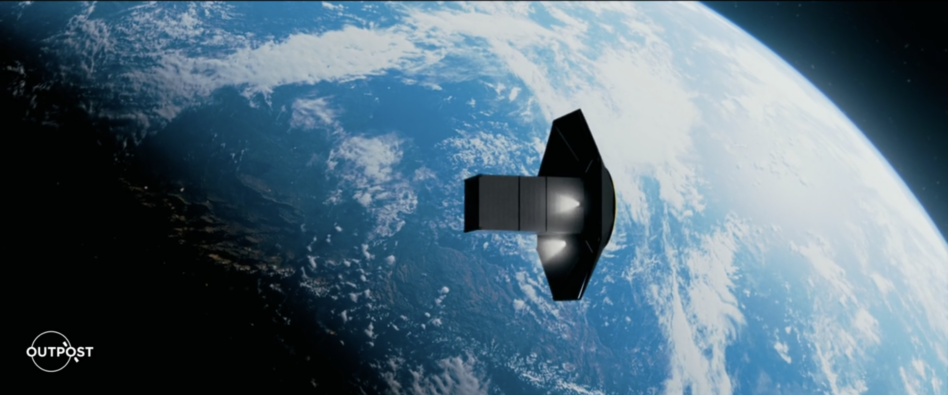

Aerospacelab, a satellite manufacturer, is one of Europe’s top-funded space startups.

Since its founding in 2018, Aerospacelab has raised over $60M, including a $45M Series B announced in 2022 led by Airbus Ventures and XAnge.

The company offers vertically integrated satellite manufacturing capabilities, from designing and manufacturing subsystems to producing satellite platforms and integrating payloads. Aerospacelab also offers in-house satellite operations, overseeing the entire process from design, build, launch, and post-commissioning services.

The company’s first in-orbit demonstration was launched on the SpaceX Transporter 8 rideshare mission. Since then, it has flown a series of additional satellites on Transporters 9 and 10. The company has eight satellites in orbit, all performing their mission.

US footprint: Aerospacelab recently established a US factory to expand its market reach and compete for large Space Development Agency contracts.

- The SDA is all about diversification. It’s why the agency is building in LEO. It’s why they are planning for hundreds of smaller satellites instead of relying on a few large ones. It’s why they insist on a diversified supply chain.

The SDA has asked its prime contractors to diversify their subcontractors to avoid reliance on single sources for critical components. Given Aerospacelab’s flight heritage and position as the largest EU satellite manufacturer, this SDA diversification push drove the company to open a US subsidiary and facility.

Company Overview

Aerospacelab’s core business is satellite and component manufacturing. Key customers include Xona, Vyoma, ESA, and European defense agencies. They recently received a contract from MDA Space to provide 200 battery charge regulators as part of the MDA AURORA constellation, which moves them into work as a prime provider and marks their first contract for mass production.

Satellite Manufacturing: Aerospacelab offers turnkey and cost-efficient satellite bus manufacturing ranging from 60 kg to 1,000 kg for custom orders, with vertically integrated production lines supporting rapid output.

- The company uses in-house developed subsystems, which allows for flexibility in accommodating payloads of various sizes with divergent power needs.

- Aerospacelab has designed the Versatile Satellite Platform (VSP), a satellite bus platform ready to support a variety of LEO missions. With a standardized modular core design, VSP is quickly adapted for a wide range of payloads, including optical imagery and radio frequency detection instruments.

Other offerings: In addition to satellite manufacturing, Aerospacelab offers post-launch operations and is building its own constellation of optical, multispectral, high-resolution, and RF sensing satellites.

- AMOS acquisition: Earlier this year, Aerospacelab acquired AMOS, a Belgian company specializing in optical systems for space applications. The acquisition will help AMOS bring its product to market, enable further vertical integration, and add optical expertise for EO payloads.

Production capabilities:

- Monnet Center factory: Operational since July 2022, with a capacity of 25 satellites per year, but can reach up to 40 annually on a double shift.

- Charleroi megafactory: The Charleroi facility is slated to come online in 2026. The factory is optimized for mass-producing up to 500 satellites per year. The facility has 7,000 square meters of production area and 4,000 square meters of clean room.

- US factory: The company is opening a US facility to capitalize on strong US demand and defense contracts. The facility will have a capacity of 75-100 satellites per year.

Company Strengths

In-house Design + Manufacturing: Around 90% of the satellite subsystems are designed and produced in-house. The company expects this figure to increase to 99% by 2026.

- Vertical integration reduces satellite manufacturing costs by eightfold, according to the company.

- In-house manufacturing also ensures high-quality standards, full transparency, and schedule control. On-time delivery helps keep build and payroll costs under control.

Scale: The company has more than 350 employees worldwide. By 2026, Aerospacelab will have three production facilities capable of pumping out hundreds of satellites per year.

Flight Heritage: The company’s on-orbit satellites are equipped with various sensor types (RF-sensing, VHR, Multispectral). All design, manufacturing, assembly, integration, and testing are completed in-house, allowing Aerospacelab to manufacture satellites in less than a year.

- Notably, the company had three consecutive nominal satellite deployments that were commissioned in record time, a key differentiator for rapid deployment needs.

ESA support: Emerging as one of the largest EU satellite manufacturers, Aerospacelab has an inside track to secure build demand for large European sovereign and commercial constellations. The company has received significant ESA contracts for tech demos.

Challenges

Startup → Maturity: The company is building out two facilities—including a 500-satellite capacity megafactory. The Charleroi megafctory will be one of the largest satellite manufacturing facilities in the world. Aerospacelab will need to manage costs through the production ramp as it transitions from a startup to a mature entity

- Mitigant: Building in the EU could help the company maintain cost efficiency due to lower workforce costs and state support. The company secured funding in 2022 that closely matches its ramp goals and demand signal.

Demand: Aerospacelab will need to find customers to fill the demand for its mega-facility, which can produce 500 satellites per year.

- Mitigant: Aerospacelab is focused on telecom and sovereign constellations, such as IRIS², which will need to be manufactured in Europe. Along with IRIS², the company anticipates securing another large telecom constellation for broadband and direct-to-device, which will offer a recurring revenue opportunity.

Industry and Competition

The company’s competitors include NanoAvionics EnduroSat in Europe (although NanoAvionics doesn’t have the capability to mass-produce satellites), and Terran Orbital, Apex, York, and Blue Canyon in the US.

Small Sat Manufacturing market: Applications include in-orbit demonstrations, small constellations for technology and science demonstrations, and EO. Customers are new space, governmental institutions, and space agencies

Telecom Satellite Manufacturing Market: Applications include satellite platforms for large telecom constellations and subsystems. Typical customers are satellite integrators and telecom operators.