Image: Redwire

Last month, NASA Administrator Bill Nelson visited Redwire Space’s headquarters in Jacksonville, FL, and said the city has become “the center for space technology.” To be fair, Nelson was a three-term Florida senator…so he’s not entirely impartial.

Nonetheless, Redwire has helped make Jacksonville a space hub, with its corporate HQ and 37,000 square foot facility. Redwire was one of many space companies to SPAC in 2021, and began trading on the New York Stock Exchange with the $RDW ticker in September.

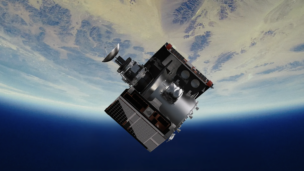

- Redwire’s technology capabilities span 3D printing, deployable structures, solar power, avionics, and in-space biotechnology.

- Driven by M&A, the Florida company has steadily built up a portfolio of capabilities. One especially notable acquisition was Made in Space.

- Redwire itself is the product of a 2020 merger between two companies, orchestrated by AE Industrial Partners.

- Redwire made ~$140M last year.

Eyes on the prize

Payload spoke with Andrew Rush, president and COO of Redwire, to hear more about the past, present, and future of the company.

- Heritage: “We were the first to manufacture functional parts off the face of the planet,” Rush said.

- In-space manufacturing: “The largest challenge for operationalizing” and adopting the technology “is actually getting those first operational customers.”

- Corporate strategy: “We intentionally have brought together amazing technologies that have flight heritage, that are just penetrating markets, that customers trust…and [we’re] building upon that.”

- Key users: Rush highlighted human spaceflight, commercial space companies, and national security customers as “the three pillars, in my view, of the second golden age of space.”

- The future of spacecraft: It’s not built around “single-use satellites or the tallest hill upon which to do communications and remote sensing, but to leverage the environment to do manufacturing.”

ISAM, not OSAM

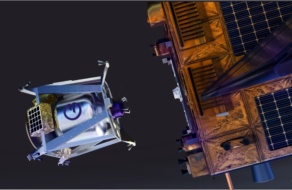

- ISAM = in-space servicing, assembly, and manufacturing

- OSAM = on-orbit servicing, assembly, and manufacturing

It’s a small distinction, but Redwire is very intentional in its use of ISAM. “I think ISAM captures a lot more of the promise and potential of manufacturing in space,” Rush said. “We’re not only talking about the ability to do manufacturing on-orbit or in microgravity, but also on other moons and planets.”

Looking forward: NASA awarded Redwire a ~$74M contract to develop OSAM-2 (or Archinaut One). This will be a key demonstration mission for Redwire’s Archinaut platform, which consists of robotic actuators, 3D printing technology, and other modular capabilities. The north star = creating spacecraft in space, rather than building them on Earth and then launching them.