Relativity is in the final innings of prep work for “Good Luck, Have Fun,” its first orbital flight attempt. The Relativity team is integrating Terran 1 in its Space Coast hangar right now, and plans to roll the rocket out to the launchpad in the coming weeks.

While all eyes may soon be on Terran 1, Relativity’s 3D-printed, 1,250 kg rocket only tells part of the story.

The launch unicorn says it’s been laser-focused on parallel development of the much-larger Terran R (20,000 kg, first flight targeted for 2024). Relativity has spent hundreds of millions on its Terran R this year alone and plans to have more than half its workforce working on the program by next year.

This week, Relativity lifted the wraps on its Stargate 4th Generation 3D metal printer, which can print objects up to 120 feet long and 24 ft wide. The company is also scaling up its presence and test facilities at NASA Stennis.

Payload sat down with Relativity boss (and Pathfinder alum) Tim Ellis to discuss the company’s recent announcements, Terran 1’s first flight, and more. Perhaps of particular interest to our audience, Ellis shared his thoughts on where the launch market is headed and why Relativity could be poised to win serious medium-lift market share.

“We’ve been taking risks and leaning into long-term success consistently at Relativity,” Ellis said. “One of our core values is audacity, so we’ve always been audacious.” And the company is ready to talk more openly about why its decision to pursue dual tracks of development (i.e., Terran 1 and Terran R simultaneously) could soon be vindicated.

Find our conversation with Ellis below, lightly edited for clarity and length.

You’ve been keeping busy, judging by all these announcements. Where should we start? Terran 1 is probably the elephant in the room.

Let’s talk first about the launch date. So, I know I mentioned once we were through first stage testing, we would start to talk a little bit more concretely about launch dates. Before I even get to that, I’ll cover what we’ve completed in stage testing.

In stage testing, which is the ground test campaign we do before the first launch, we’ve done a full-flight duration stage two test at our test site out at NASA Stennis Space Center. That is a full second stage, and the last test before it’s in flight and on the way to space. And we’ve done a full-flight duration acceptance test. We also did a full-flight duration acceptance test of just that engine before attaching it to the stage.

Essentially the vehicle has already undergone, from a propulsion system perspective, two full-flight duration tests. The actual launch itself would be the third. We’ve taken a similar approach with stage one, which has nine engines, and every single engine has already done a full-flight duration acceptance test.

And then, the integrated stage itself has done six ignitions of all nine engines and 185 cumulative seconds of hot fire. Throughout all of that, there were no engine or major hardware swaps needed. So, the hardware is looking really good. We’re mostly just tuning the start-up sequence, different red lines, and safety systems to make sure that we got all of the data we needed to feel confident to go into launch.

Besides the ignition getting to full power with all the engines, the biggest piece of data was tuning and honing the autogenous pressurization system. Despite this being a 3D printed rocket, it’s also the first methane-fueled rocket to fly and one of the first to use autogenous pressurization. Terran 1 really looks closer to a miniature Terran R than it does to a lot of the other small satellite launch vehicles that are out there.

I remember autogenous pressurization from our last conversation. Can you explain what that is to me like I’m five?

Normally I would say what’s more standard is you carry helium composite overwrapped pressure vessels – so carbon fiber tanks – that are filled with helium. Those are often submerged in the liquid oxygen to make them very, very cold, so the helium won’t turn into a liquid. But because it gets very cold, it gets quite dense.

And so you can fit a bigger amount of helium in a smaller vessel, and then that helium would go through a heat exchanger, usually on the rocket engine, and heat up. It goes from very cold to much hotter. That would then feed back into the propellant tank as the propellant level goes down.

Essentially, think of a rocket’s primary structure as a big tank full of liquid propellant. As the rocket flies, of course, the propellant level is decreasing, and you’re actually expending that propellant. You’re creating a huge empty volume inside the rocket tank that has to be filled with something in order to keep the pressure.

The pressure is maintained by that helium pressure. Now, the problem with that is you have to carry helium and all these separate helium pressure vessels. And that’s actually the system that has caused rocket failures. For example, at SpaceX with the Falcon 9, the on-pad failure was due to the helium system. It’s quite tricky to operate.

For autogenous pressurization, you actually use the rocket propellant itself and run it back through a heat exchanger. We use liquid oxygen with a liquid oxygen heat exchanger, and then the liquid methane with a liquid methane heat exchanger on the rocket engine. Pulling off that gas is what goes back into the tank and then pressurizes it.

It’s just more complicated, because the gaseous oxygen or gaseous methane touches liquid oxygen and liquid methane within each tank. And so you have what’s called ullage collapse. So essentially, it turns back into liquid because it will actually get cold again. So you have to get data in actual testing in order to validate the models, and that’s what we did for stage one. So, I don’t know if that’s explained like you’re five. But that’s as simple as it gets.

You can only abstract away the complexity of autogenous pressurization so much. Maybe there’s a five-year-old wunderkind out there reading this and they’ll get it all much better than me. With Terran 1, there’s the 3D-printing aspect, methane engines, and all the testing you just mentioned. What would you say is industry standard, versus kind of new and bespoke for Relativity?

I would say full-flight duration engine acceptance testing is pretty standard. From the little you can glean from looking at other small satellite launch companies, I think other people have done full-duration engine tests. Getting to 80+ second stage testing like we did with stage one is way more robust. Also, same with a full-flight duration for stage 2.

I would say those activities are significantly more robust. Leading into this first flight, we know that we would be the first venture capital-backed company in history to succeed on launch one, should we get all the way to orbit.

And this is a lot of what I want to get to today: besides the first launch date for Terran 1, we’re talking to our customers. It’s very interesting to hear their perspective on how much they’re looking forward to milestones with Terran R and Aeon R. They’ve been in development for 2+ years. That momentum continues to be important to winning all of these customer contracts versus Terran 1, which customers have really told us is a development step on the way to Terran R. That’s really the rocket it looks like the market just needs to exist as soon as possible.

You’ve had these dual tracks of development, and it’s pretty obvious why that’s been really important for you. Will Terran 1 even fly commercially? Once you make it to orbit, what is the future of that rocket? And of course here I’m caveating with the assumption that you make it to orbit.

I think the best way to frame it is that we’re just listening to what customers want. Like I mentioned, Terran R has been in development for over two years.

In hindsight, that was a big bet. We saw this market opportunity for a second highly disruptive, quickly moving, medium-to-heavy lift launch company, similar to what SpaceX has developed with Falcon 9 and is now reinventing with Starship.

And if you really look across the industry landscape, nobody has stepped up to that plate. You have Ariane 5, but they’re transitioning to Ariane 6. There’s ULA, but they’re going from Atlas V to Vulcan. Of course, New Glenn is still in development, but there’s not a lot of public info about it, necessarily, and when it’s really flying. And then there’s Neutron from Rocket Lab.

Then, of course, with the whole Ukraine-Russia conflict, the Soyuz launch vehicle is completely offline. That’s about 20% or so of the world’s launch capacity. Then, Amazon Kuiper went and effectively bought all of the rest of the world’s commercial launch capacity through about mid-2026 or so.

There’s a huge shortage of medium to heavy-lift launch vehicles, with no one super-well positioned to capture it other than I believe us. We have the launch sites and the one million square foot factory. We just announced a really large extension at Stennis, which I think we had over a year ago but are just announcing it now.

So, we’ve actually had quite a lot of progress. I would say this year that about half of our resources went into Terran R, with hundreds of people and hundreds of millions of dollars we’ve spent on Terran R already this year. Next year, more than half will go to Terran R (vs. Terran 1).

That’s a lot of context, but to your question, that context is important. Like, yes, we have certainly sold a lot of Terran 1s. We’ve actually transitioned some of those customers on to Terran Rs. And Terran R really is the rocket, it seems, that the market needs as soon as possible. And it’s the biggest opportunity.

There’s nothing definitive after the first launch of Terran 1. Ask: “Well, what does the first flight success from a customer lens look like?” While the rocket-loving engineer in me would want to say, “Get to orbit. Orbit or nothing,” the business leader in me knows that customers are going to tell us what good enough looks like for the first flight. And we’re asking what the level of data collection we need for the first flight to then have confidence that we’re able to execute on Terran R, solve all the hard rocket problems that we need to solve, and prove the 3D printing tech works.

I really think that the 3D printing tech working on Terran 1 is the most important thing. Really, in my mind, that’s about getting past Max Q—the max stress on the rocket—which is around 80 seconds for our first flight. That’s a big inflection point for us, with the world’s first 3D-printed rocket.

In the words of the founder of your former employer Blue Origin, would you say you’re customer obsessed? To your point about benchmarking the success of a launch not to technical standards but what your current or future customers would want.

I mean, yes. What’s interesting though is it’s not because I learned that from Jeff or Blue Origin. You know, Relativity’s now almost seven years old and I’ve learned that winning customers and market share is the thing to do to prove that you’re not just building a really interesting technology but building something that people want.

It’s even the Y Combinator motto. Make something people want. And I think that’s always the biggest fear from investors: that you’re going to make something that works, technically, even if it’s very ambitious, but then nobody wants it.

I’m very excited that of the five publicly announced customers for Terran R that make up the $1.2B in contracts, we won 100% of the contracts we went after. We were competing against a lot of those other medium- to heavy-lift launch companies that are striving to come online. The fact that we won 100% of the time is a testament to the actual progress we’ve made.

We’re now starting to test a significant amount of hardware on the Aeon R and Terran R programs. I think the investment ahead of time was really important to have this high momentum in that particular market space.

I feel like the pejorative term that an investor might use is “science project,” when referring to something that’s being built that people don’t want. And you’re really harping not just on your technical progress, but market progress. That doesn’t come through as much on a day-in, day-out basis if you’re a rocket company, because people just want to see the rocket.

But that’s not to say we’re targeting anything less [with Terran 1] than hitting orbit. Because of the robust ground testing, I do think we have a real shot. Like, we’re not intentionally targeting anything less, but I think it’s more about really defining what success looks like on the first launch from the customer lens.

What else can you say about the first Terran 1 launch?

I mentioned a lot of the technical readiness that we have for launch. We’re integrating the rocket horizontally in our hanger right now. The plan is to roll it out to the launchpad and do a static fire test, which is just a few seconds of lighting all nine engines, but with the whole second stage and everything stacked. Then, launch right after.

From a technical readiness perspective, we believe we’re gonna be ready in the next couple weeks here. There are still three external factors that could impact our launch timeline.

The first is the Artemis launch schedule limiting some dates and availability even for static-fire testing, and we have to plan around it.

Then, with the holidays coming up, there’s a DoD program called HARP, the Holiday Airspace Release Program, which frees up commercial airspace during the highest volume travel days over the holidays: Thanksgiving, Christmas, and New Year’s, essentially. From Dec. 20 onwards through New Year’s, you really cannot launch.

And the last is the FAA launch license. We’re regularly in touch with them, and we’re one of the first companies to go through the Part 450 process. We’re making good progress and did get acceptance, formally, of our technical methodologies for the launch license.

That was this last week, which was a huge step forward. That’s official recognition of our technical methodologies for debris mitigation and modeling, and architecture analysis software, which we wrote in-house by the way. I believe we’re the first company on a first rocket to write our own trajectory simulation software in-house. That will be very helpful for reusable rockets, so we wanted to get a leg up on it.

I wonder when the license comes if I’m going to find out about it first from y’all or the automated Twitter account. It’s so quick.

Yeah, they’re neck and neck. We’ll try to tweet about it as soon as we get it.

How often are your mentions people tagging you and asking “wen launch?”

One of our investors is Jared Leto, and he’s also somewhat of a friend, and he gave me really good advice—he told me to never read the comments.

Let’s turn to the news of the day: your fourth-gen Stargate metal printer, and how you say it’s a step change in manufacturing capabilities. Can you walk us through what the biggest improvements are with this printer?

Yes, of course, and we’re super excited to announce this. It’s been in development for quite some time, and it’s certainly the biggest breakthrough on printer tech of any of the iterations that we’ve had. Generation #1, #2, and #3 of the Stargate print systems essentially use very similar fundamental deposition physics of a single print wire, then a heat source to melt the wire, as well as a vertical print orientation.

What changed between each of those various printers were the material science systems. We were coming up with new alloy chemistries and iterations of the new materials. The actual physical architecture of those printers kept changing. We were figuring out: do we put the printed part on the lift? Or the robots on the lift? Or the printed part on the lift? We flip flopped back and forth to get bigger and bigger build volume.

But then with this printer, we completely changed the architecture paradigm. Now, we actually print the rocket horizontally up to 24 feet in diameter and 120 feet long, and pull the part out from the Stargate print build platform. It’s a very counterintuitive idea, and I think I’m gonna get lots of questions about it.

I even had lots of questions when our team came up with it around sagging and how the heck it was even gonna work. It looks really complicated and a lot harder, but as it turns out, the horizontal printing together with a new print head with multiple metal wires fed in simultaneously has allowed us to increase the print speed from 1x up to 7x. We’ve even pushed it as hard as 12x, but we’re just baselining it for these first development printers.

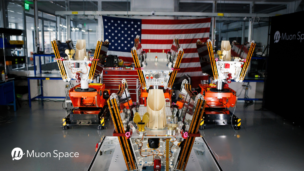

These printers we’ve released are the development and production printers for Terran R.

We’re building out and we’ve got four active right now. Each one at full production rate can build four Terran Rs per year. But we’re building 12 out in the first half of the factory, although we still have space for a huge production farm of additional V4 printers in the future.

Can you say how much the printers cost? Or offer a ballpark estimate?

I haven’t talked about specific numbers. I can tell you they’re cheaper than you would expect. What’s hard about the printing isn’t the hardware cost. It’s actually very scalable.

When you look at the math of how much you’ve been printing—the whole fuselage for 10 hours—it’s actually incredible what we’ve achieved, and it’s incredibly cheap. When you look at the full cycle of all the parts we can integrate into a single piece, which is really the advantage of printing, the printers themselves are very low cost.

What’s more important is productivity. How many rockets can they build? Then, also, how do we get from where we’re at today to four per year, per printer? So that’s an aspirational goal that I certainly believe will get to over the next couple years.

Is it still too premature to be thinking or talking about using this technology to print things for others?

We do actually have a very small, very focused team looking at what comes next on other products. It’s tiny. But yeah, I think there’s some interesting areas and really, it could even be linked to the long-term vision of Relativity, which is building an industrial base on Mars, right? I’m serious about that.

I totally take you at your word.

Yeah, I am serious about that.

When you look at the rate-limiting steps, like sending people, I think step one is showing you can send people and cargo there in a really huge, heavy-lift rocket. Very clearly, you can see that with what Starship is doing. I’m a big believer in Starship and want them to succeed so that Mars does have a shot at happening within our lifetime.

Then, the other piece is manufacturing technology to build things. And I think that’s going to even start with spare parts. 3D printers initially will probably be used to increase mission reliability. If something breaks and you can’t fix it, you’ll want the ability to have a compact flexible manufacturing system that can find a way to build a part. You can’t really predict what part that will be, so it’s one way to increase initial mission reliability.

The next rate-limiting step, I think, will be energy production. When you look at Mars and its distance from the sun, solar panels’ efficiency drops. They’ll work to an extent, but we really want to generate very large quantities of energy in a compact way. So, when there aren’t readily available hydrocarbons at scale, similar to Earth, I do think things like fusion reactors are going to be quite interesting.

We do have a very small partnership with a major fusion company. We’re starting to do material sample tests using the Stargate print system just to see if there’s a way that we could help manufacture the core of a large-scale fusion reactor. There are some additional products that we’re looking at that are still pretty mission-aligned.

I have a friend who runs another fusion company and am certainly optimistic that the whole industry is close to a big breakthrough on net-positive fusion. I’m optimistic that it can also be a technology that could really be a game-changer in solving climate change on Earth as well.

Adjacent to energy, with Good Luck, Have Fun, if you make it to orbit, you’d be the first company in history to have a methane-fueled rocket reach orbit, correct?

Yes, so we’d have three firsts.

We’d be the first one to succeed on launch one as a company that’s never launched a rocket before. We’d be the first 3D-printed rocket—and yeah, largest 3D-printed object by far, certainly in orbit. Finally, we would also be the first methane-fueled rocket to launch.

What have you learned with methane?

Along with learning on the pressurization systems and Terran 1 having nine engines all together on the first stage, with a gas generator cycle engine, all of those decisions inform the Terran R architecture and methane.

It’s much more advantageous for reusability than kerosene. I think, you know, that SpaceX has gotten very far with Falcon 9 reuse with just kerosene. But there’s a reason they’re switching to methane. Blue Origin is using methane for New Glenn, and even Vulcan is methane. Rocket Lab’s rocket is methane, because it’s much more highly reusable.

Kerosene is a liquid at room temperature, and it’s basically like oil, more or less. It’s kind of like a version of gasoline, almost, or a fuel. It’s just more highly refined in a very specific chemistry. But it actually leaves kind of a sludge or film in all of the fluid systems it flows through. After launch, there’s also a process called coking.

It’s very acid-y and ashy when it burns. Basically it’s just really dirty. You have all of this dirty stuff after a reusable rocket has landed that you go in and clean, which takes a good amount of time.

You have to take parts apart and put them back together. With methane, the way to clean it after it’s launched is you just open the valves and eventually it’ll all boil off to gas. It has no residue. It really doesn’t do the ashing or coking process, because there’s a lot less carbon in it, relative to RP1.

And so it’s just a lot cleaner. For highly reusable rockets, where you really want to get to operational reusability, similar to an airline, that really is kind of the only real way to do it. You could do it with hydrogen as well, like liquid hydrogen, like the Space Shuttle, but that has a lot of its own challenges. It’s quite expensive and such a small molecule that it dissolves in certain metal alloy structures and makes them really brittle. The materials you have to use for a hydrogen rocket end up being not as strong as the materials that you can use for a methane rocket.

Even the advantage of hydrogen’s higher specific impulse kind of actually goes away, because it’s less dense and you have to use less strong materials. It ends up being kind of a wash.

So, yeah. That’s kind of getting in the weeds, but it’s an important distinction and I think everyone’s collectively come to the same conclusion.

Returning to Terran R, you say you’re investing hundreds of millions into that program?

Yes. We already have. We’ve already done hundreds this year, and I’d imagine, tens of millions last year. And nearly half of the company will start working on Terran R next year.

It’s a huge fraction of our effort, and we’re finally hitting some pretty big public milestones. We started sub-scale testing of the thrust chamber assembly. We’re working up to a full-scale thrust chamber assembly hot fire. So it’s a 258,000-pound-thrust engine. We’ll test that chamber towards the beginning of next year at Stennis.

We’ll also have our first full engine build with turbopumps, valves, chamber, and everything coming together, which will also be in the beginning of next year. Of course, there’s these new printers, which are really designed and developed to make Terran R.

All of this just reflects the fact that it didn’t happen overnight. We’ve been taking risks and leaning into long-term success consistently at Relativity. One of our core values is audacity, so we’ve always been audacious. Anyone that’s been closely paying attention is connecting the dots.

We have this significant manufacturing innovation and investment with the Stargate fourth generation. There’s also large investment and our test infrastructure expansion at Stennis. Then, as I’ve mentioned, Terran 1 really is quite a bit more complicated than it needed to be for a 1,250 kilogram payload launch vehicle. But that was on purpose, so that we could gain key learnings that serve Terran R in the future.

All of that really maps towards the longer-term vision. Too often, people that follow us focus on whether, like, 3D printing the tanks makes sense or if it’s nearsightedness. But we’re really about playing the long game, and ultimately, we’re playing to win. There’s this market opportunity to be the next great launch company in medium- to heavy-lift.

And it’s not just low Earth orbit constellations. I’m actually really surprised by the market reaction we’ve gotten from geosynchronous satellite providers, of which several have signed with us. So, Terran R is gonna launch geosynchronous satellites.

All of that’s really because if you honestly look at it from a low-cost, disruptive perspective, SpaceX and Falcon 9 are really kind of the only option right now. But they’re doing their own satellites, and so there’s an interesting kind of conflict of interest there.

And there’s got to be a second company. Like I can’t see a future where there’s only one that’s really being disruptive. And since we’re still private, and we didn’t do a SPAC, with our share price down 50% or what have you, it actually gives us a lot more flexibility to be long-term focused and to focus on playing to win.

In a post-Starship world, some think there aren’t going to be any other launchers. But you’re saying it can’t just be one. There’s not really a good argument to be made that if all this was monopolized, it would still be as disruptive. There just has to be competition, right?

Our real long-term north star is Mars and building this multiplanetary future. I actually think Starship will be successful to be very clear. I would never bet against that team and what they’re building. They’ve consistently proven over and over they can figure it out. I do think that perhaps it could take a little bit longer, and I think to get to the cost structure they talk about, that certainly could take a bit longer. But I think it’s gonna work.

What’s interesting is Terran R is also going to be a fully reusable rocket and it’s really based on where the commercial market is.

If you look at the analogy of the airline industry, the square-cube law says that a lot of transportation that uses propellant scales significantly better the larger it is. So this is true of cargo shipping containers and aircraft like the A380, which is the largest commercial aircraft ever built. It was the cheapest per passenger, per mile, per seat in the world. But it ended up not being a full commercial success because you had to fly routes from one location to another that required the whole plane to be full. And it was very difficult to get it to be full enough with just those routes that it made economic sense.

Dollar per kilogram is the metric often used in the industry. It’s a good metric, but no customer is paying per kilogram. They’re just paying for 20 satellites that weigh X kilograms, which they need to launch to this single orbital plane.

And if there’s 20 satellites weighing 1,000 kilograms each—Terran R’s payload capacity is 20,000 kgs—we could launch every single one of the satellites to a single orbital plane. We would charge an amount that makes sense, knowing we’re also building towards a fully reusable rocket. And if you had extra payload capacity, it wouldn’t necessarily matter to that particular customer.

This is really just a way of saying that long term, I do expect the rocket industry to look a little bit more like commercial aviation. Different payload sizes make some sense, but you still gotta hit a critical inflection point where it’s low enough cost per satellite to make sense and acquire customers. And that’s one of the other big reasons Terran R has won a lot of these deals. Just the 20,000 kg payload size versus even 8,000 is a really big difference.

Yeah, I hear you. Well, Tim, you’ve been really generous with your time. Before we hop off, is there anything else that we haven’t touched on that you think it’s important our audience should know? Any questions I should have asked but didn’t?

Just to hammer the point home on your earlier question on Terran 1. We’re so excited to do this first launch. We’re quite confident going into it that we have gotten a lot of the data that we need, in order to feel good about going into this first launch and learning from it. Despite the focus on Terran R, we certainly are putting everything we can into Terran 1, to ensure this first launch goes as well as we want it to.