Today, Hawthorne-based Launcher announced the appointment of Tim Berry as head of manufacturing. Berry spent over eight years across town at SpaceX, most recently serving as manager of additive manufacturing.

- Before that, he led teams integrating SpaceX Dragon Crew and Cargo spacecraft. And from 2013 to 2019, Berry oversaw the production of 90 flight-rated Falcon 9 upper stages.

“With an insanely cool product mix driven by a talented design team and a laser focus on quality, cost, and performance, I look forward to facilitating Launcher’s growth,” Berry said in a statement.

- Last June, Launcher opened a 24,000-sq-ft. production facility, which prominently features 3D printers from Velo3D and EOS.

- From the get-go, Launcher is pursuing a vertically integrated model by developing “every major part” of its spacecraft and rocket engines in-house.

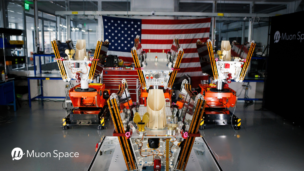

Launcher’s product lineup:

- Orbiter = an orbital transfer vehicle. Last week, Launcher said it had booked three additional SpaceX Transporter rideshares for Orbiter. Launcher’s first Orbiter is set to launch in October, with the three additional missions taking place in Jan., April, and Oct. 2023.

- E-2 = Launcher’s closed-cycle, staged-combustion liquid rocket engine. Launcher says a single E-2 will power the first stage of its forthcoming rocket.

- Light = A small rocket with an advertised 150 kg-to-LEO payload capacity. Launcher is targeting 2024 for Light’s maiden flight.