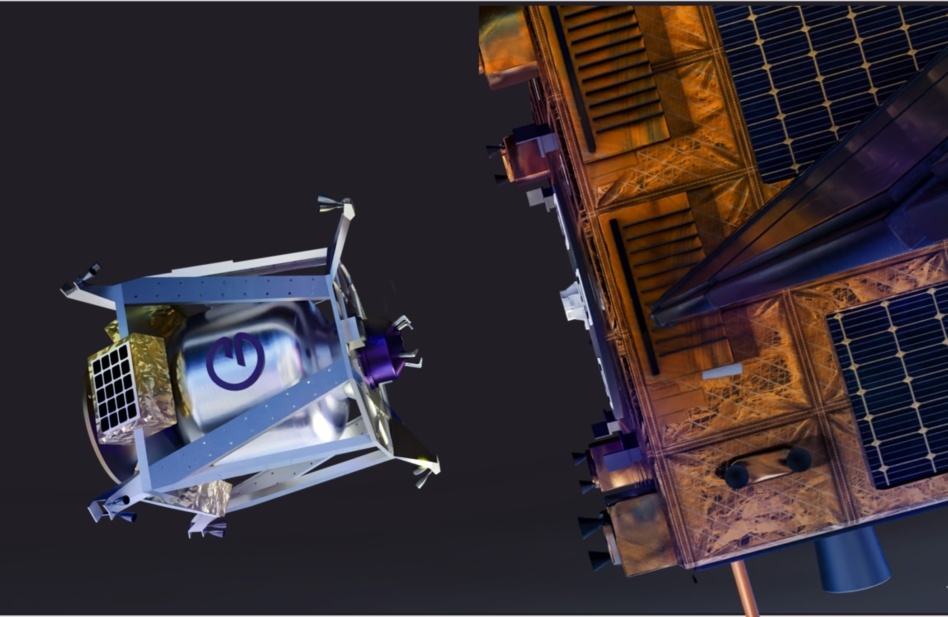

Orbit Fab, a company trying to crack on-orbit refueling, is ready to take on missions in space after successfully wrapping up testing on its automated GRIP refueling mechanism, the company announced on Tuesday.

At an AFRL facility in Albuquerque, NM, Orbit Fab’s GRIP connected to and refueled a satellite fitted with the company’s RAFTI (Rapidly Attachable Fluid Transfer Interface) fuel port at multiple different angles and velocities. Next stop, space.

“Our main technology risk is now behind us,” CEO Daniel Faber told Payload.

The next test: Orbit Fab has already shipped its GRIP and RAFTI hardware to government and commercial customers in the US, UK, and Japan, and the refueling technology is expected to launch in late 2025.

The company has secured three different contracts as part of Space Force’s Tetra-5 initiative to test in-orbit refueling and servicing. These include:

- A refueling payload for AFRL

- Fuel delivery services with the DIU

- A refueling interface for Space Systems Command at LA Air Force Base

Fill ‘er up: Unlike gas stations in New Jersey, Orbit Fab offers clients the option for full or self-service. Either way, the technology will extend the lives of spacecraft far beyond their available fuel storage.

Typically, satellites are given a lifetime supply of propellant before launch through fill-drain valves that are essentially sealed shut afterwards. With Orbit Fab’s RAFTI gas caps, satellites can be refueled in space numerous times and carry less propellant into orbit than they would otherwise need. The GRIP mechanism is able to autonomously attach onto a satellite without the need of a mechanical arm, which further lowers costs.

What’s next: Orbit Fab’s goal for space is one where its refueling architecture is ubiquitous—and execs say that future is nearing reality.

“Right now, we’re able to fulfill our order needs, [but] we’re expecting that we’re going to get to capacity,” Orbit Fab’s Chief Commercial Officer, Adam Harris told Payload.

To solve this problem, the company is looking for manufacturing partners to build components at scale and pass along lower costs to customers.