Rosotics is on a mission to revolutionize additive manufacturing.

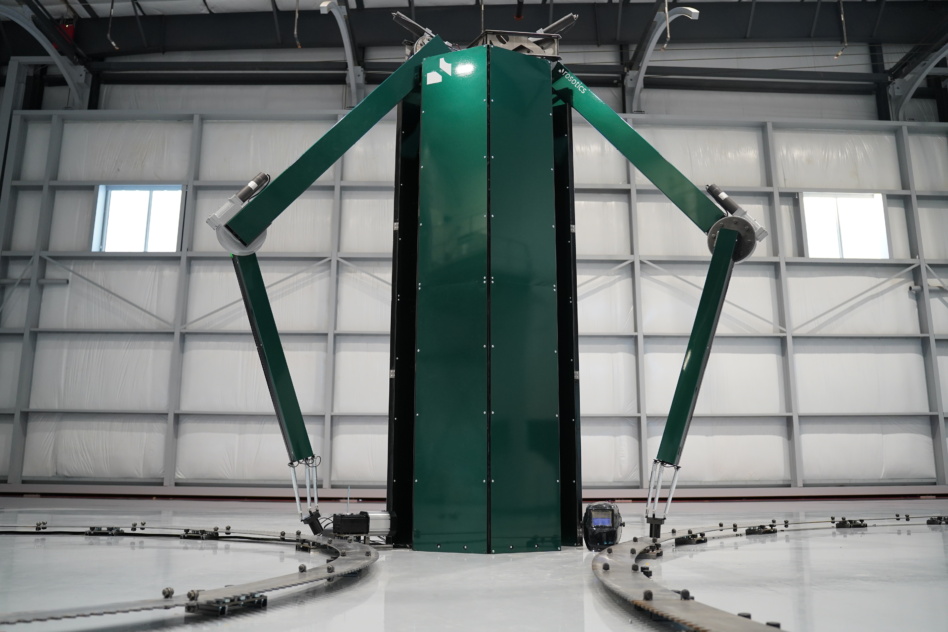

This morning in Mesa, AZ, the 3D-printing startup will debut the first completed prototype of its Mantis printer—a huge, unfolding contraption capable of printing 45 kg of material per hour on the power from a standard 240V outlet. The first printers are marked for delivery in October this year, with a sticker price of $95,000 a pop.

The story so far

Rosotics raised a $750,000 pre-seed led by Draper Associates back in November 2022. Since then, the team has been laser-focused on developing the first prototype of Mantis.

- The 3D printer is built to manufacture large-format components up to 30 feet in diameter.

- Mantis prints in aerospace-grade steel and aluminum.

- Eventually, Rosotics aims to increase the types of feedstock that can be used in Mantis and broaden sales to other industries, including energy and maritime applications.

And there’s little doubt of the merits of 3D printing in aerospace. On Wednesday, Relativity launched the first 3D-printed rocket, passing Max-Q on the first attempt and proving its thesis about the durability of additively manufactured structures.

“That’s a testament to the robustness of 3D printing, and what you can produce, and how strong those parts can be,” Christian LaRosa, founder and CEO of Rosotics, told Payload.

Rapidly inducting

Traditional 3D printers use a laser to heat and melt feedstock material to build structures. According to LaRosa, they generally print from one nozzle, consume loads of energy, and can be dangerous to operate because of the laser.

Rosotics’ solution is a new method called rapid induction. Instead of heating the feedstock with an outside source, the technique uses induction to generate heat from within the feedstock, creating a liquid flow for printing. This method consumes less energy than today’s techniques.

“Having a new process that is more efficient [and] does away with the laser entirely allows you to not only push more mass through that nozzle, but you can also run more nozzles at the same time,” said LaRosa.

The induction problem

Rosotics cracked induction for ferromagnetic materials like iron alloys, including steel, early on. Using inductive printing on non-ferromagnetic materials, like aluminum, posed a bit more difficulty.

To solve the second issue, Rosotics designed a printing nozzle using a blend of materials, including cobalt, that enables the machines to print with aluminum, using the same power and output metrics as they’ve reached for steel, LaRosa said.

Now what?

Now that Rosotics has officially debuted Mantis, the startup has a whole lot of deal-making and line production ahead of it.

On the customer side, LaRosa said that Rosotics has begun conversations and conducted site visits with aerospace companies as well as industrial firms in adjacent fields. The startup has been holding off on closing any deals until debuting Mantis, but now they’re open for business.

To ramp up production, Rosotics is establishing an assembly line at the Falcon Field airport in Mesa. LaRosa intends to scale production to “dozens of these machines each quarter” in fairly short order.