The Space Force is still hankering for more maneuverability in space, judging by a new $3M SBIR award for Rocket Propulsion Systems (RPS) to build an orbital transfer vehicle around its Centurion engine.

“We’re starting with low-cost engines,” RPS cofounder and CEO Max Ismailov told Payload. “We will be selling our engines for $150,000—that’s unprecedented. Normal engines that have similar performance are $1.5M at least.”

For context, SpaceX CEO Elon Musk has said the internal cost of his company’s more powerful Raptor and Merlin engines is less than $1M each, thanks in large part to mass production.

Tug of war: The straight-to-Phase II SpaceWERX/AFWERX award will see the Kent, WA-based startup build a space tug with 80 kg of payload capacity to hand over to the service in 2027. Ismailov said the vehicle would be able to support a variety of payloads, but couldn’t share the Space Force’s plans for the vehicle.

“This type of investment reflects the Department of the Air Force’s broader goal to stay ahead of emerging threats by tapping into dual-use innovations that can enhance mobility, agility, and resilience in space,” SpaceWERX said in a statement to Payload.

Dome zone: RPS expected to receive this contract six months ago, but policy changes in Washington delayed the award. While the selling point of this vehicle remains its low cost and hoped-for high maneuverability, it’s now being framed as a solution for….yup, Golden Dome.

Ismailov said the vehicle could support the various space segments of the new missile defense architecture—“You can place, say, 16,000 of our OTVs in space…so that you have enough of them to intercept the ICBM as it flies to us.”

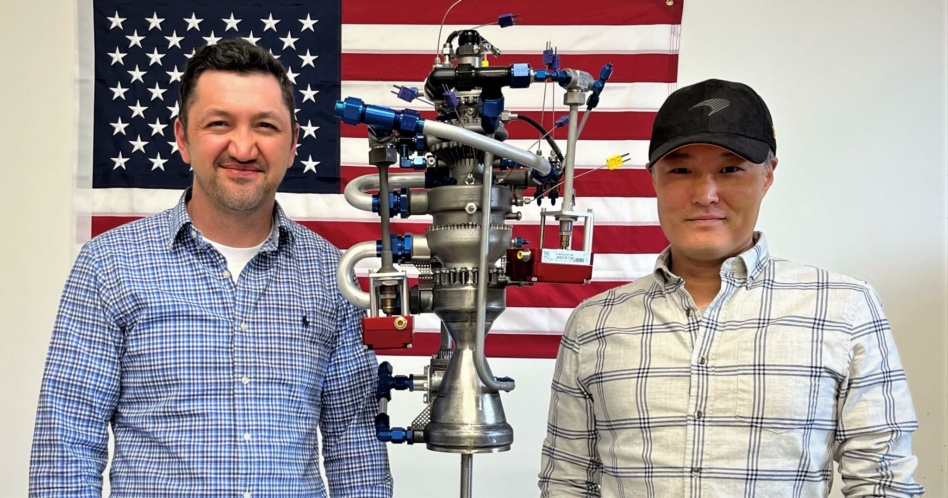

Fire away: Before that, however, the company needs to finish engine development. Ismailov has a long record in the industry, working at Blue Origin, SpaceX, Stratolaunch, and Firefly on propulsion problems.

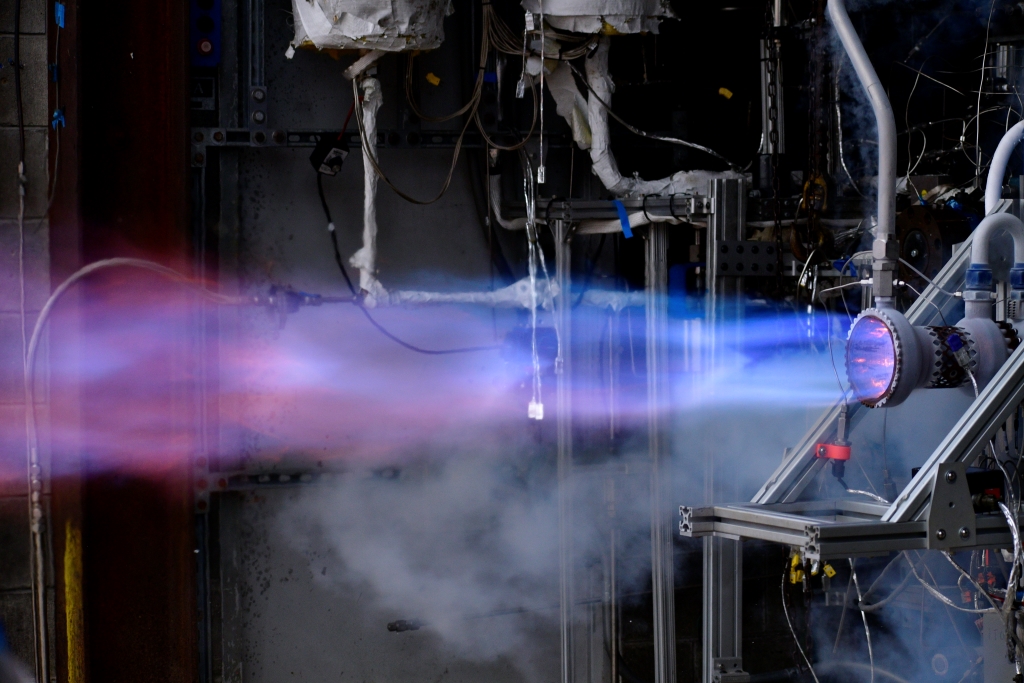

To build Centurion, a cheap methalox engine with 1.5 metric tons of thrust, the company is relying on optimizing production across different manufacturing modes, as well as low-cost alloys. Thrust chamber testing is complete, and RPS hopes to begin manufacturing next year.

These boots: The company is entirely bootstrapped, Ismailov says, on top of $5M in government funding—beginning with a NASA grant for nuclear propulsion research in 2019. The aspirations of RPS are much higher and will require raising private capital..

“We started off with engines, we’ve now moved into OTVs, and ultimately we will be rounding out the company as a manufacturer of small launch vehicles which launch from Earth to LEO,” cofounder and COO Ankur Saxena said.