SpaceWorks Enterprises unveiled the details of its first in-orbit demo reentry flight today.

The mission, funded in part through NASA’s $500,000 TechLeap Prize, will bring Astral Materials’ semiconductor crystal manufacturing payload to orbit aboard SpaceWorks’ RED 25 reentry capsule.

With the help of a NASA-selected orbital transfer vehicle, the capsule and payload will operate on-orbit for three to 12 months. The capsule will then reenter the atmosphere and splash down in the ocean, where SpaceWorks will attempt to recover it.

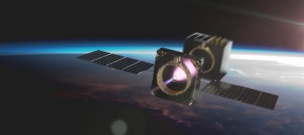

Made to orbit: SpaceWorks’ RED 25 reentry capsule is about 0.8 meters in diameter and can support payloads up to 25 kg. As part of the TechLeap prize, SpaceWorks has developed environmental controls—and other custom features—to support Astral’s semiconductor crystal manufacturing capabilities.

SpaceWorks flew an early version of its reentry capsule technology to the ISS in 2017, and another to near-space for a high-altitude drop test in 2021, but the 2026 mission marks the kick-off of the company’s commercial offering.

While competitor reentry company Varda Space Industries is building its own in-space manufacturing capabilities, SpaceWorks’ focus is on building the platform for others to manufacture in microgravity.

“We think that the silicon semiconductor manufacturing is the most promising technology right now,” Tyler Kunsa, SpaceWorks’ VP of defense and space, told Payload. “But we are really developing these systems to be—not payload agnostic—but able to support a number of different in-space manufacturing payloads.”

SpaceWorks’ long-term vision is to increase its flight cadence to once per week. It also aims to support commercial missions for in-space manufacturing of biologics, fiber optics components, and other, more exotic materials, according to Kunsa.

Astral-ogy: For Astral Materials, the mission’s baseline goal is to build flight heritage of its semiconductor crystal manufacturing technology, but Astral’s fingers are crossed that the reentry mission will result in real products it can sell.

“We have customers who are interested…[But] since it will be our first time in orbit, we are not promising anything.” Dr. Jessica Frick, Astral’s cofounder and CEO, told Payload.

Ultimately, Astral succeeds by building a reliable supply chain from space, Frick said, which depends first and foremost on having partners that can return their semiconductor crystals unharmed and on time.

Kármán lineup: SpaceWorks aims to upgrade its in-orbit reentry capsules to handle larger payloads for manufacturers and the DoD.

It’s currently developing a capsule to host payloads up to 50 kg, and to perform its own dynamic maneuvers on orbit, effectively eliminating the need for an OTV partner to get the capsule on the right reentry trajectory.

SpaceWorks has also partnered with Earthly Dynamics to incorporate a guided parafoil into the reentry capsule, in an effort to return future capsules with precision. The parafoil will help lessen the g-forces of reentry,enabling a wider range of manufacturing payloads and helping SpaceWorks support future DoD point-to-point logistics missions.

Correction: An earlier version of the article misrepresented the size of the RED 25 capsule. It is 0.8 meters in diameter.