The push to expand US advanced defense manufacturing continues in Ohio, where engine specialist Ursa Major won a $4M grant from America Makes, a non-profit run out of the National Center for Defense Manufacturing and Machining.

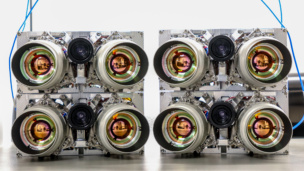

Ursa will use the money plus an additional $1M to purchase a Velo3D Sapphire XE Metal 3D printer to begin printing flight-qualified engine components at its Youngstown facility after three years of commercializing a NASA-developed copper alloy.

The end goal is to produce 50 to 100 liquid-fueled rocket engines a year, Ursa Major COO Nick Doucette told Payload.

Nat sec checks: The investment is designed to accelerate development of the company’s Hadley engine, first flown on a Stratolaunch Talon hypersonic vehicle this year, and the forthcoming Draper, a larger engine for hypersonic or small launch that is being funded by the Air Force Research Lab.

Ursa also received a $14.5M grant for solid motor production at the same facility in August, with the hope of producing much-desired missile propulsion systems at high volume to meet the needs of the US military, which is concerned about China’s investments in space and missile technology and the supply attrition seen in Ukraine’s conflict with Russia.

Alloy addition: Since 2021, Ursa Major has been working with a copper-chrome-niobium alloy, GrCop-42, designed by NASA for 3D printing applications. The metal will be used in thrust chambers to minimize the need for additional cooling. This grant is intended to take that development project and start putting out flight-qualified components.

“That’s the direction we took it—yes, it’s printable, let’s make it printable and usable, specifically getting test time on our stands here,” Doucette said.